Arm-Tex is a proud OPW bottom loading arm distributor. For over 120 years, OPW Engineered Systems has created reliable equipment for the bulk loading and unloading industry. Known for their loading arms’ high quality, OPW has become an industry standard across the world. Their bottom loading arms can give your operation a variety of benefits that simply cannot be achieved with top loading designs.

Features of OPW Bottom Loading Arms

For instance, since bottom loading takes place on the ground, it’s much safer. Since the operator is always on the ground, no one has to worry about falling off of the top of the vehicle, which is otherwise a constant threat. Bottom loading systems also create fewer turbulence tank compartments. This makes loading and unloading procedures far less dangerous since it curbs the generation of static electricity.

Bottom loading can also increase loading efficiency by letting you have multiple compartments loaded simultaneously.

This gets your tanks filled faster. To make things better, loading and unloading are much faster since bottom loading systems allow for quicker connections. They can also be  connected using CCAM and groove fitting, dry disconnect, API coupler, or Acme threaded hammer union. These loading arms are also great at reducing vapors, which can become an environmental hazard if not dealt with properly. OPW bottom loading systems can be adapted to recover displaced vapors during the loading process, taking this concern out of the equation.

connected using CCAM and groove fitting, dry disconnect, API coupler, or Acme threaded hammer union. These loading arms are also great at reducing vapors, which can become an environmental hazard if not dealt with properly. OPW bottom loading systems can be adapted to recover displaced vapors during the loading process, taking this concern out of the equation.

Better yet, bottom loading arms are much simpler to assemble than top loading tacks, and they are cheaper to build, as well. Since you can move more material in less time with bottom loading racks, you can also expect savings through time efficiency. Plus, Arm-Tex offers a line of loading equipment that can reduce spillage and leaks while loading and unloading petroleum products, chemicals, and liquefied gases such as LPG, LNG, and propane.

Types of OPW Bottom Loading Arms

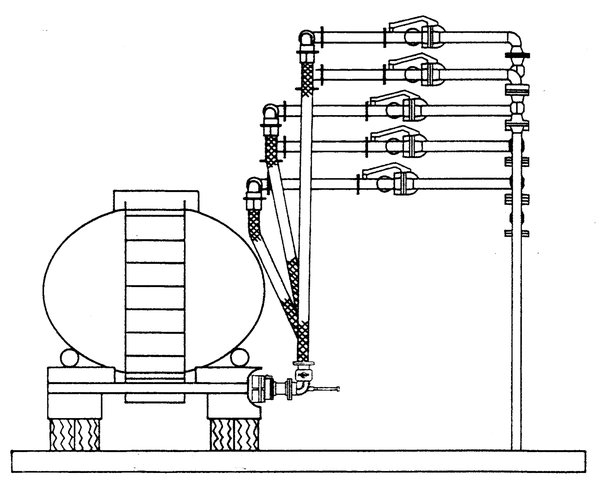

Bottom arms include the G-32-F unsupported boom-type arm which is great for applications that have variable elevations and require scissor-back storage. The M-32-F “A” Frame loader can be compactly stored for optimal clearance and it allows for multiple product applications. The AFH-32-F “A” Frame hose loader provides the same benefits as the conventional “A” frame, except it uses a flexible hose instead of piping on the secondary arm. And the short- and long-range spring balanced hose loaders (SRH-32-F and LRH-32-F respectively) are equipped with adjustable torsion springs, meet API envelope requirements, and make loading and handling a breeze.

Benefits of Buying Through Arm-Tex

For over 25 years, Arm-Tex has provided the fluid transfer and unloading industry with equipment from leading brands, such as OPW Engineered Systems. If you’d like more information about how an OPW loading arm could benefit your operation, you talk to an expert at Arm-Tex today. Whether you are looking to purchase loading arms or parts to repair them, we can give you guidance and send you the technical manuals you will need to repair an arm that you still have in service.

.08c8713e9b9e93e47b556082daf2ba52151.jpg)